Electrifying industry

We offer complete solutions for the electrification needs of industrial processes

Electric gas (air) heaters

When time is left for gas or oil, there is a need for DCS's gas handling expertise.

We combine our strong fan expertise with electric heating expertise and, if necessary,

our strong filter expertise.

Suitable processes are typically those in which solid, dusty material is dried. The end result

is a solution that can, for example, drying by heating electrifies.

MVR-drying

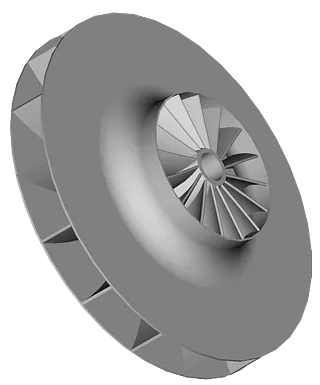

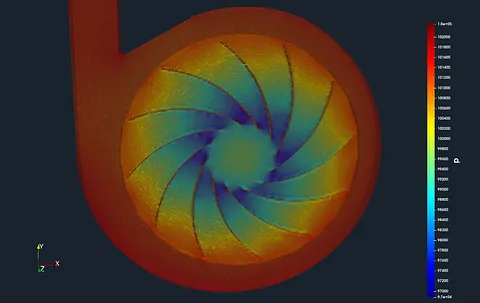

DCS has been supplying industry with fans for demanding processes for 40 years. We also know high-pressure MVR fans suitable for evaporation. We design them using our modern tools, such as CFD calculation and FEA analysis.

With the equipment of our workshop, we are able to make even large-diameter wings with high quality. We combine our scrubber expertise with our MVR fans and offer industry energy-efficient and carbon-neutral evaporation solutions based on them.

MVR heat pump

DCS fan and gas handling is an excellent basis for our MVR heat pump offering. MVR heat pumps (Mechanical Vapor Recompression) have several significant advantages:

-

Energy efficiency: MVR heat pumps are highly energy efficient as they use only a small amount of electrical energy to recompress steam compared to how much heat energy they produce.

-

Low operating costs: Since MVR heat pumps significantly reduce energy consumption, they can significantly reduce operating costs.

-

Low emissions: MVR heat pumps reduce the use of fossil fuels, resulting in lower carbon dioxide emissions and environmental impact.

-

Versatility: the Heat pumps can be used in many different industries, such as chemical, food and wastewater treatment.

-

Easy integration: MVR heat pumps can be easily integrated into existing systems, making them a flexible solution for a wide range of applications.

These advantages make MVR heat pumps an attractive option for improving energy efficiency and reducing environmental impact.